Monday, July 25, 2011

Saturday, July 23, 2011

Wednesday, July 20, 2011

CLEANING CARBURETOR - avoid accidents

After dismantling the carburetor from the engine, make sure to plug the engine intake hole with rug to prevent other objects to accidentally fall inside.

Before dismantling the carburetor and while the bowl is still filled with fuel, check the accelerator pump to see if it is working good by moving the throttle and see if its spurting fuel from the venturi.

Clean the outside of the carburetor before dismantling to avoid the danger of dirt going inside. It may clogged the jets later on.

If gasoline is the available cleaning agent, always REMEMBER that it is HIGHLY FLAMMABLE and you must provide adequate ventilation in the working area. The use of electric fan is advisable if there is no free air circulation.

If its your first time, be careful in dismantling. Some parts may fall and you will have a hard time figuring out where it came from.

Clean the jet hole with a small wire and to make sure the holes are not clogged, blow air into the hole from your mouth and feel the air coming out from the other side with your finger.

Make sure that it is thoroughly clean before putting it back together. Change the gaskets with a new one.

Saturday, July 16, 2011

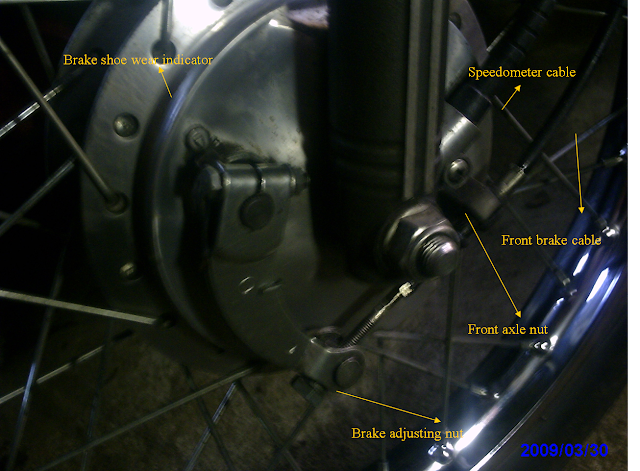

FRONT WHEEL REMOVAL

Put the motorcycle in its center stand and raise the front wheel off the ground by placing a support block under the engine. Remove the speedometer cable, front brake adjusting nut, and remove the front brake cable from the brake arm. Remove the axle nut, axle, and the wheel.

Clean the gears and change with a new grease. Check your bearings. Clean your brake shoes and smoothed them with a sandpaper. Check the ovality of brake drum with a caliper.

For installation, reverse the removal procedure and tighten the axle nut to specified torque (6.0 kg-m, 43.5 ft-lb). Adjust the brake and test for free wheel rotation after applying the brakes. Do it for several times.

Clean the gears and change with a new grease. Check your bearings. Clean your brake shoes and smoothed them with a sandpaper. Check the ovality of brake drum with a caliper.

For installation, reverse the removal procedure and tighten the axle nut to specified torque (6.0 kg-m, 43.5 ft-lb). Adjust the brake and test for free wheel rotation after applying the brakes. Do it for several times.

Wednesday, July 13, 2011

BRAKE SHOE WEAR

If the brake wear indicators aligns when brake is applied, brake shoe must be replaced.

Place the motorcycle on the center stand and remove the rear wheel axle nut.

Use a screwdriver to remove the axle.

Remove the drive chain.

Remove the rear brake adjusting nut and rod from the brake arm.

Remove the wheel and check the brake. This is a single leading shoe. Pull the lock pin out and remove the washer. Pull one brake shoe and the shoes will come out together with the springs. Clean the dust and smoothed the brake shoe and drum with a sandpaper. Or change it with a new one. Put everything back in the reverse order and make sure to put grease on the brake camshaft and pivot post. Tighten the axle nut to specified torque. (6.0 kg-m, 43.5 ft-lb).

After installing the wheel, apply the brakes and check for free wheel rotation when released. Do it several times. Don't forget to check or adjust the brake lights.

Place the motorcycle on the center stand and remove the rear wheel axle nut.

Use a screwdriver to remove the axle.

Remove the drive chain.

Remove the rear brake adjusting nut and rod from the brake arm.

Remove the wheel and check the brake. This is a single leading shoe. Pull the lock pin out and remove the washer. Pull one brake shoe and the shoes will come out together with the springs. Clean the dust and smoothed the brake shoe and drum with a sandpaper. Or change it with a new one. Put everything back in the reverse order and make sure to put grease on the brake camshaft and pivot post. Tighten the axle nut to specified torque. (6.0 kg-m, 43.5 ft-lb).

After installing the wheel, apply the brakes and check for free wheel rotation when released. Do it several times. Don't forget to check or adjust the brake lights.

Tuesday, July 12, 2011

Saturday, July 9, 2011

CHECKING PISTON AND RINGS

After taking out the top, check the piston for movement sideways. it should be tight. If it's not change the piston. Also check the piston ring groove while the ring is in its groove. Insert a feeler gauge between the ring and the top or bottom of the groove and if it measures between .001" to .003' it is still good.

Try to feel the top of the cylinder for a ridge. If there is an obvious ridge, it must be re-bored oversize.

Friday, July 8, 2011

CLUTCH ADJUSTMENT

Normal clutch lever play is approximately 20mm

Pull back the rubber dust cover located at the left handlebar. Loosen the lock nut and turn the clutch cable adjuster. Check the adjustment and tighten the lock nut.

If correct free play cannot be obtained using the cable adjuster, loosen the lock nut at the lower end of the cable and turn the adjusting nut to obtain the specified free play and tighten the lock nut.

Start the engine, pull in the clutch lever and shift into gear. Gradually release the clutch lever and open the throttle. The motorcycle should begin to move smoothly and accelerate gradually.

Friday, July 1, 2011

Sunday, May 29, 2011

My Diploma

I just completed my Dan's online motorcycle repair course and I made this achievement certificate to post here as a remembrance and a reminder that whatever we want to achieve, we can get it online, in the internet.

If you want to be an airline mechanic, then Go and don't waste time!

If you want to be an airline mechanic, then Go and don't waste time!

Friday, May 27, 2011

How carburetor works

Motorcycle carburetors works on similar principles: A passageway (Venturi) is connected to the intake side of the combustion chamber. A vertical tube (jets) runs vertically from the passageway to the float chamber. As the piston executes its intake stroke, a great vacuum is created in the combustion chamber and at the same time the intake valve opens that creates a suction pressure in the venturi and the jets. A simple explanation for this is like sucking the liquid inside a bottle with a straw while the remaining space inside the bottle is kept at atmospheric pressure.

The amount of fuel flow is controlled by the needle and the needle jet. The higher the needle is lifted, the greater the fuel flow. When the needle is at its lowest, it effectively shuts off the jet. At the highest position of the needle, gas flow is controlled by the smallest tube which is the main jet. The needle, needle jet, and main jet can be change to smaller or bigger size to adjust the fuel-air mixture ratio.

Airflow is controlled by a valve. Either a butterfly valve or an airslide. The airslide works hand in hand with the needle in such a way that when the needle is lifted allowing more gas flow, the slide opens allowing more air to flow. Airslide usually have a cutaway at the bottom to allow more or less air through at throttle openings.

The pilot jet with its own airway is built to provide a trickle of fuel for tick-over. It is adjusted by a screw which opens or closes the size of the airway. This allows a smooth transition from a tick-over to faster running.

The fuel in the float bowl is kept at a constant level by the float. If the level is raised, it would cause too much gas to pass through the jets causing a rich mixture. If it is too low, it would cause a weak mixture. The fuel enters the bowl in an opening with a needle valve connected to the float. When the float is lifted, it closes the entrance at a prescribed point and as the gas is being used it will go down with the level of the liquid gas, thereby opening the entrance to allow fuel to come in.

Wednesday, May 25, 2011

Carburetor tuning

To do this the motor need to be run at speed and in a straight road with no traffic and if possible run it uphill or against the wind to ensure that the engine is puling at the greatest load. The engine must be in perfect condition and at its normal working temperature.

- 1. With the throttle wide open, the mixture is controlled only by the main jet. Test the motor at top speed on full throttle then cut the engine quickly and check the spark plug. A medium brown color around the insulator is ideal. A darker color means a rich mixture. A lighter color indicates a weak mixture. A slightly rich mixture is better than a weak one. A weak mixture could cause overheating and may damage the piston.

- 2. Throttle openings from one fourth to one fourth are governed mainly by the needle and needle jet.

- 3. Beyond the one fourth open position; the airslide cutaway has the most effect. It provides for a smooth pick-up with no ‘flat spots’ when the machine is driven away from a standstill.

- 4. When the throttle is closed, the pilot jet supplies the fuel. A second pilot outlet increases the fuel supply for a clean, smooth engine pick-up.

- 5. The carburetor should be tested in these positions. Get the engine running smooth and clean then check the spark plug.

- 6. To richen the mixture, fit a jet with a larger number. Go one stage at a time and in any case, opt for a slightly rich jet.

- 7. Adjust the tickover to get it reasonably slow and even.

- 8. Test the motor in the one fourth to one fourth open positions. It should run evenly at a steady throttle opening and pick up quickly and smoothly when accelerated. Check the spark plug.

- 9. If the mixture is seriously amiss, a larger or smaller jet will be needed. A larger means richer on all jets. It might be possible to fit a needle with a different taper. It the motor runs good on half throttle but misbehaves below this, change the airslide. Here a larger number means a weaker mixture.

- 10. Test the motor at low speeds and for a clean pick-up when gently accelerating. This is affected by the airslide and the needle. When OK, check for full-throttle acceleration.

- 11. Go over the slow-running adjustments carefully to get the best tickover. These tests often have to be repeated several times to get the best results.

Tuesday, May 24, 2011

Carburetor - slow run

In order for the carburetor to get a smooth, even and consistent tick-over, frequent adjustment will be the slow run. It should be made when the engine is at its normal working temperature and when the rest of the machine is in good condition.

- 1. Make sure that the throttle cable adjuster has enough slack before starting and running the engine.

- 2. Usually, the carburetor has two adjusting screw; the throttle stop and the pilot adjusting screw.

- 3. Turn the pilot screw clockwise until it meets light resistance and then turn it counterclockwise one and a half to two turns.

- 4. If the motor is running fast, turn the throttle stop until it runs as slow as possible without faltering.

- 5. Turn the pilot screw to speed up the engine then bring the speed back down with the throttle stop.

- 6. Repeat until the tick-over is right. Adjust the throttle cable to the right slack.

Monday, May 23, 2011

Open-Top-SEE

My funds are limited but I can’t just sit down and leave my bike park in the garage so I decided to do a top overhaul by myself and see what happens.

· I managed to dismantle the whole engine down and put it on a table.

- · Removed the chain and sprocket cover.

- · Unbolted the sprocket from the camshaft.

- · Release the chain tension rod.

- · Took out the overhead camshaft cover. The rocker arm is built in the cover.

- · Removed the cylinder head.

- · Lifted the camshaft and check the bearings. It’s OK.

I took the cylinder head to a motorcycle repair shop for a ‘grind-valve’ job. And there it is the main culprit - A broken valve guide and probably a dented valve. It has to be taken to a machine shop for repairs.

I checked the piston, piston rings, and the cylinder. No visible signs of wear and tear. It’s a still reasonably tight fit. I didn’t bother to check on the gaps because I think that it’s still good. I just check and clean the lubricating holes. I also checked the connecting rod and crankshaft bearings. There’s no perceptible rocking movement or up-and-down play.

I cleaned and change the broken gaskets and use the same old metal gasket because I’m planning to do a complete overhaul pretty soon.

I carefully refit everything back and follow the tightening sequence and feeling the right torque I set the intake and exhaust valve clearances.

After a few try the engine is running again. I tuned the carburetor and set just the minimum tickover.

I’m back on the road again. The road test make me suspect that the exhaust valve needs more regrinding. Well that will be taken care of the next time.

Sunday, May 22, 2011

The hard climb

My motorcycle engine misfires at over 500RPM so I dismantled the air cleaner and start the engine. I positioned my fingers to block the carburetor intake side where the air cleaner was connected and twist the accelerator handle to speed the engine. It didn’t misfire so I put the air cleaner back and positioned the choke lever in the middle so the airflow valve is now blocking the air and allowing only less air through. The engine runs good or so it seems. Riding my motorcycle with the choke lever in the middle position is unnatural and I suspect that something is wrong.

When I used my motorcycle going up to Baguio, it was overheating and I have to cool it off 5 times before reaching the top and the cool weather of Baguio City made it run better. We (me and Norma) barely made it to the top because the engine has a weak pull and I actually decided once while we were on our mid-climb to go back down to Laoac, but realizing that we had already spent most of our money and our best option is to pray that our ride will bring us to the top, we continued the climb.

God heard our prayers and we’re safely backed home. I took the motorcycle to an expert mechanic for assessment and was told to prepare a big sum of money as he suspect that the engine needs a major overhaul. I need time to think as my funds are limited.

Subscribe to:

Posts (Atom)